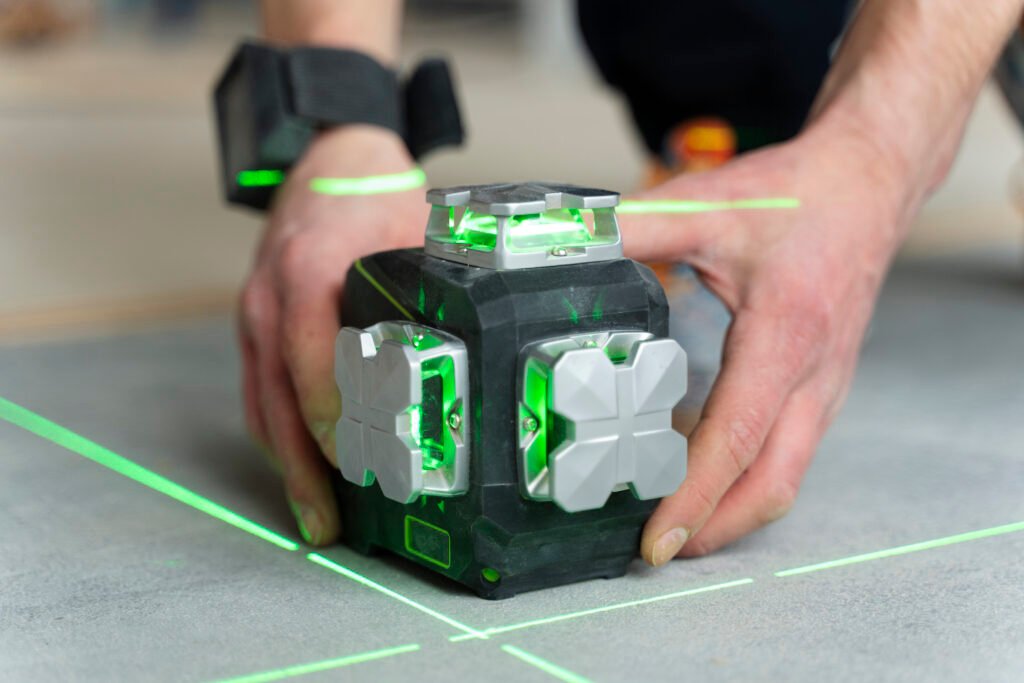

Laser Distance Sensors with IoT Telemetry for Structural Monitoring

Achieve pinpoint accuracy in deflection and deformation tracking with LiDAR or Time-of-Flight sensors integrated with IoT telemetry

Laser Distance Sensor (LiDAR or ToF) with IoT Telemetry

Laser distance sensors using LiDAR (Light Detection and Ranging) or Time-of-Flight (ToF) technology have become essential for high-precision structural monitoring. These sensors use laser pulses to measure exact distances with millimeter-level accuracy, making them ideal for detecting deflection, displacement, vibration, and surface deformation. Paired with IoT telemetry, these measurements are instantly transmitted for remote viewing, analysis, and alerting—making them perfect for critical infrastructure and smart asset monitoring. Tilt Deflection Angle delivers robust laser distance sensor solutions to businesses across North America. As a growing B2B leader in innovative structural monitoring technologies, we integrate precision hardware with smart data pipelines. Our laser-based systems help engineers and facility operators monitor infrastructure health in real-time, reduce inspection costs, and improve decision-making accuracy across a wide range of applications and industries.

Core Components of Laser Distance Sensors

In addition to offering products and systems developed by our team and trusted partners for Laser Distance Sensor (LiDAR or ToF) with IoT telemetry, we are proud to carry top-tier technologies from Global Advanced Operations Tek Inc. (GAO Tek Inc.) and Global Advanced Operations RFID Inc. (GAO RFID Inc.). These reliable, high-quality products and systems enhance our ability to deliver comprehensive technologies, integrations, and services you can trust.

Hardware

- LiDAR and ToF Laser Distance Sensors – Motion & Position Sensors track stress-induced motion in skyscrapers and insurance-covered structures.

- IoT Telemetry Modules (LTE, LoRaWAN, NB-IoT) – LoRaWAN Accessories offer long-range data relay for continuous claim-based structural assessment.

- Edge Processing Units – IIoT manage real-time insights for finance/insurance actuaries overseeing industrial plants.

- Weatherproof Enclosures – Zigbee Accessories help protect smart crack and strain sensors in policy-critical locations.

Software

- Device Configuration Tools: Calibrate sensor ranges, detection zones, and communication intervals remotely.

- Real-Time Visualization Platforms: Monitor distance readings and historical data on cloud-based dashboards with mapping overlays and graphs.

- Custom API Access: Connect to enterprise systems for automated analysis, reporting, or control functions.

Cloud Services

- Live Telemetry & Data Logging: Receive continuous readings with timestamped logs for audit and compliance.

- Remote Alert Management: Set up automated alerts via SMS, email, or system notifications.

- Data Storage & Redundancy: Maintain secure, backed-up databases with options for edge-cloud hybrid models.

- Analytics & Insights: Use advanced algorithms to detect trends, surface anomalies, and inform predictive maintenance.

Key Features & Functionalities

- Ultra-Precise Laser Measurement - Millimeter-level accuracy, ideal for structural health monitoring in sensitive environments.

- Real-Time Wireless Communication - IoT telemetry ensures seamless, uninterrupted data flow from sensor to dashboard.

- Non-Invasive Monitoring - Measures distance without physical contact, reducing wear and enabling remote placement.

- Wide Operating Range - Supports long-distance measurement—from a few centimeters to hundreds of meters, depending on sensor type.

- Smart Thresholds & Alerts - Receive proactive warnings when deformation exceeds defined limits.

- Ruggedized for Harsh Environments - Industrial enclosures and coatings protect sensors in dust, rain, extreme heat, and vibration.

Benefits

- Immediate Operational Awareness - Real-time insights into structural changes enhance safety and reduce inspection frequency.

- Highly Scalable System - Easily expand sensor networks across multiple assets or sites.

- Reduced Downtime - Early detection of movement or failure risks allows proactive repairs and maintenance.

- Precision You Can Trust - LiDAR and ToF sensors offer unmatched accuracy for mission-critical applications.

- Data-Driven Decision Making - Historical trends and live feeds empower smart asset management strategies.

Applications

- Bridge and overpass deflection measurement

- Tower tilt and displacement monitoring

- High-rise façade or curtain wall movement tracking

- Earthquake and seismic response analysis

- Rail alignment and deformation sensing

- Slope stability and geotechnical monitoring

- Industrial automation and clearance control

Industries

- Civil and Structural Engineering

- Transportation and Infrastructure

- Energy and Utilities

- Mining and Geotechnical Engineering

- Aerospace and Defense

- Smart Cities and Urban Planning

- Oil & Gas and Petrochemical

Integrations & Compatibility

- Works with major cloud platforms: AWS, Azure, Google Cloud, and IBM Cloud

- Compatible protocols: MQTT, CoAP, HTTPS, LoRaWAN, and NB-IoT

- Integrates with: Building Management Systems (BMS), SCADA, and GIS platforms

- Developer support: SDKs and APIs for Python, Node.js, and C++ environments

Relevant U.S. & Canadian Industry Standards

- ASTM E3066 (U.S.)

- IEEE 1588-2019 (U.S.)

- ANSI C136.25 (U.S.)

- CSA A23.3-19 (Canada)

- CAN/CSA-C22.2 No. 61010-2-201 (Canada)

Case Studies

Case Study – U.S.: Structural Health Monitoring of a Suspension Bridge in Oregon

A public infrastructure authority in Oregon deployed LiDAR sensors with IoT telemetry to monitor real-time deflection across the span of a suspension bridge. The system delivered sub-millimeter precision and sent immediate alerts during wind load events. Maintenance teams were able to plan structural checks based on sensor data, reducing inspection time by 40%.

Case Study – U.S.: Industrial Equipment Alignment in Ohio

A steel production plant in Ohio integrated Time-of-Flight sensors on moving crane systems to monitor beam displacement and alignment. The IoT telemetry setup transmitted readings to the plant’s centralized maintenance system, improving uptime and operator safety through predictive alignment checks.

Case Study – Canada: Façade Deformation Detection on a High-Rise in Toronto

A construction firm in Toronto used LiDAR-based sensors on the exterior of a newly constructed high-rise tower to detect deformation during thermal expansion and wind load conditions. The sensors provided real-time updates via LoRaWAN and enabled compliance with structural safety codes throughout the first-year settlement phase.

Looking to integrate advanced laser distance sensors with IoT telemetry into your monitoring strategy?

Contact us now to speak with one of our experts. At Tilt Deflection Angle, we’re ready to help you deploy scalable, reliable systems tailored to your needs